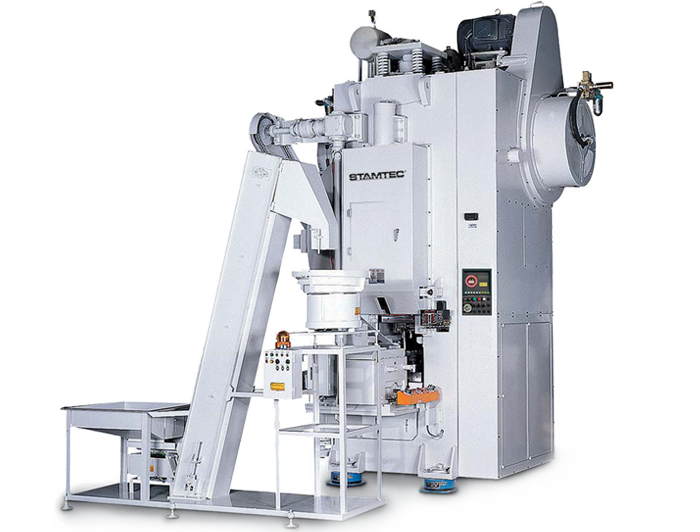

Mechanical Forging Press

For many components, cold or hot forging offers crucial production efficiencies & benefits like strength, integrity & material savings.

REQUEST A CUSTOM QUOTE

For many components, cold or hot forging offers crucial production efficiencies & benefits like strength, integrity & material savings.

REQUEST A CUSTOM QUOTEStamtec’s KW1 Series Cold and Semi-Hot Forging Knuckle-Joint Presses, especially when coupled with feeder and transfer equipment, is effective and efficient in forging and drawing thick sheet material.

The wet clutch on these cold and semi-hot forging presses delivers high torque and performance at relatively low air pressure. Friction linings run in an enclosed oil bath, providing a very long lived clutch and brake with efficient heat dissipation, low vibration, minimal noise, reduced lining wear, and lower air consumption, even at high single-stroke rates of production.

TONNAGE RANGE: 300 - up to 4,000

Read the specs and press advantages below and then contact us for help identifying the knuckle-joint press your operation requires.

| MODEL KW1-300 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 330 |

| Metric Tons | 300 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 4.72 |

| mm | 120 | |

| Speed | SPM | 20 ~ 40 (20 ~ 45) |

| Slide adjustment | in. | 0.59 |

| mm | 15 | |

| Die height | in. | 17.72 |

| mm | 450 | |

| Bolster area | in. | 43.31 x 37.40 |

| mm | 1100 x 950 | |

| Bolster thickness | in. | 7.09 |

| mm | 180 | |

| Slide area | in. | 43.31 x 33.47 |

| mm | 1100 x 850 | |

| Working height | in. | 35.43 |

| mm | 900 | |

| Side frame opening (window) (F-B x H) | in. | 23.62 x 22.44 |

| mm | 600 x 570 | |

| Maximum upper die weight | lbs. | 2204.62 |

| Kgs | 1000 | |

| Main motor | HP x P | V.S. 30 x 4 |

| MODEL KW1-400 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 440 |

| Metric Tons | 400 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 4.72 |

| mm | 120 | |

| Speed | SPM | 20 ~ 40 (20 ~ 45) |

| Slide adjustment | in. | 0.59 |

| mm | 15 | |

| Die height | in. | 17.72 |

| mm | 450 | |

| Bolster area | in. | 43.31 x 37.40 |

| mm | 1100 x 950 | |

| Bolster thickness | in. | 7.09 |

| mm | 180 | |

| Slide area | in. | 43.31 x 33.47 |

| mm | 1100 x 850 | |

| Working height | in. | 35.43 |

| mm | 900 | |

| Side frame opening (window) (F-B x H) | in. | 23.62 x 22.44 |

| mm | 600 x 570 | |

| Maximum upper die weight | lbs. | 2204.62 |

| Kgs | 1000 | |

| Main motor | Hp x p | V.S. 40 x 4 |

| MODEL KW1-500 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 551 |

| Metric Tons | 500 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 5.91 |

| mm | 150 | |

| Speed | SPM | 20 ~ 40 |

| Slide adjustment | in. | 0.59 |

| mm | 15 | |

| Die height | in. | 17.72 |

| mm | 450 | |

| Bolster area | in. | 49.21 x 39.37 |

| mm | 1250 x 1000 | |

| Bolster thickness | in. | 8.66 |

| mm | 220 | |

| Slide area | in. | 49.21 x 39.37 |

| mm | 1250 x 1000 | |

| Working height | in. | 46.65 |

| mm | 1185 | |

| Side frame opening (window) (F-B x H) | in. | 23.62 x 30.32 |

| mm | 600 x 770 | |

| Maximum upper die weight | lbs. | 3306.93 |

| Kgs | 1500 | |

| Main motor | HP x P | V.S. 50 x 4 |

| MODEL KW1-650 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 716 |

| Metric Tons | 650 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 5.91 |

| mm | 150 | |

| Speed | SPM | 20 ~ 40 |

| Slide adjustment | in. | 0.59 |

| mm | 15 | |

| Die height | in. | 17.72 |

| mm | 450 | |

| Bolster area | in. | 59.06 x 39.37 |

| mm | 1500 x 1000 | |

| Bolster thickness | in. | 8.66 |

| mm | 220 | |

| Slide area | in. | 59.06 x 39.37 |

| mm | 1500 x 1000 | |

| Working height | in. | 49.8 |

| mm | 1265 | |

| Side frame opening (window) (F-B x H) | in. | 23.62 x 22.44 |

| mm | 600 x 570 | |

| Maximum upper die weight | lbs. | 3858.09 |

| Kgs | 1750 | |

| Main motor | HP x P | V.S. 60 x 4 |

| MODEL KW1-800 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 881 |

| Metric Tons | 800 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 9.84 |

| mm | 250 | |

| Speed | SPM | 20 ~ 35 |

| Slide adjustment | in. | 0.59 |

| mm | 15 | |

| Die height | in. | 25.59 |

| mm | 650 | |

| Bolster area | in. | 59.06 x 39.37 |

| mm | 1500 x 1000 | |

| Bolster thickness | in. | 9.84 |

| mm | 250 | |

| Slide area | in. | 59.06 x 39.37 |

| mm | 1500 x 1000 | |

| Working height | in. | 51.18 |

| mm | 1300 | |

| Side frame opening (window) (F-B x H) | in. | 23.62 x 30.32 |

| mm | 600 x 770 | |

| Maximum upper die weight | lbs. | 3858.09 |

| Kgs | 1750 | |

| Main motor | HP x P | V.S. 75 x 4 |

| MODEL KW1-1000 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 1102 |

| Metric Tons | 1000 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 7.87(9.84) |

| mm | 200(250) | |

| Speed | SPM | 20 ~ 40(20 ~ 35) |

| Slide adjustment | in. | 0.59 |

| mm | 15 | |

| Die height | in. | 25.59 |

| mm | 650 | |

| Bolster area | in. | 59.06 x 39.37 |

| mm | 1500 x 1000 | |

| Bolster thickness | in. | 9.84 |

| mm | 250 | |

| Slide area | in. | 59.06 x 39.37 |

| mm | 1500 x 1000 | |

| Working height | in. | 51.18 |

| mm | 1300 | |

| Side frame opening (window) (F-B x H) | in. | 23.62 x 30.32 |

| mm | 600 x 770 | |

| Maximum upper die weight | lbs. | 3858.09 |

| Kgs | 1750 | |

| Main motor | HP x P | V.S. 100 x 4 |

Specifications available on request.

Give us a call at 931-393-5050 or complete our request form.