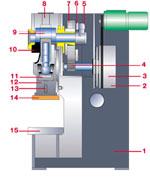

Stamtec’s Mechanical Presses (a.k.a. OBG, OBS, OBI, or C-frame) undergo finite element analysis prior to manufacturing to ensure proper design, superior strength and maximum resistance to deflection

Stamtec’s Mechanical Presses (a.k.a. OBG, OBS, OBI, or C-frame) undergo finite element analysis prior to manufacturing to ensure proper design, superior strength and maximum resistance to deflection

The Stamtec SC2 two-point straight side press (a.k.a. double crank press) is designed for stamping relatively long, narrow parts at high single stroking rates or in continuous mode, using either blanks or coil stock; or for running progressive dies that need the longer bed area to accommodate long dies with multiple stations. The SC2 series double crank press provides a large die area at a very economical price, especially for applications where it can be used instead of a straight side press.

TONNAGE RANGE: 121 - 275

DELIVERY TIME: 18-20 weeks

Review the advantages and features below and then contact us for assistance in identifying the right double crank press for your application.

Each Stamtec mechanical stamping press can be customized to meet a wider range of SPM, stroke, rating point (BDC), bed and other specifications and dimensions.

2-Point Straight Side Presses (SC2 Series)

2-Point Straight Side Presses (SC2 Series)Our double crank press series includes many features standard that are only available as options on other machines.

Heavy frame supplies a solid base to resist deflection and provide accurate stampings and longer die life.

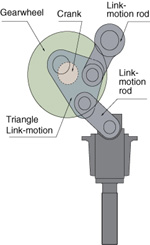

Link motion drive design reduces slide speed in the working stroke by 40 percent, prolonging tool life and reducing noise and vibration.