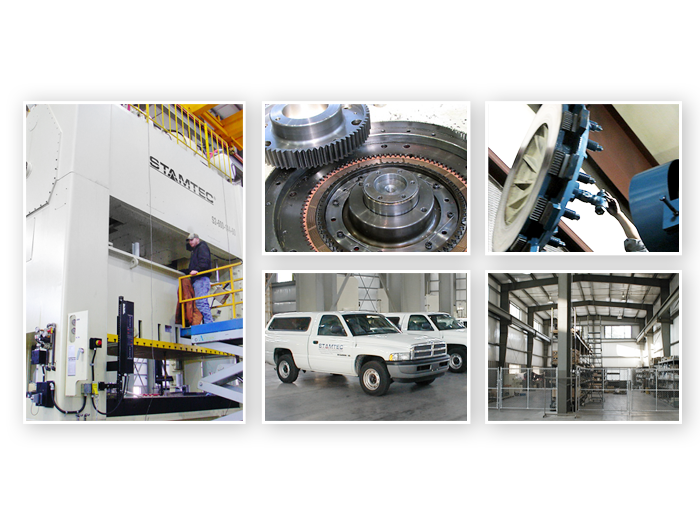

Field service & replacement parts where & when you need them

Field service & replacement parts where & when you need them

Press Accessories and Upgrades to enhance production efficiency.

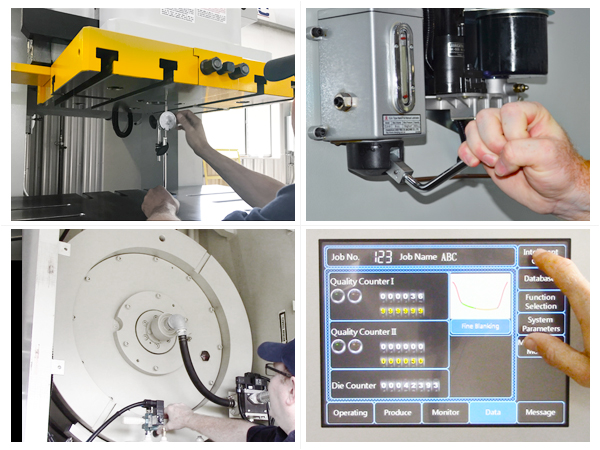

The Stamtec project management, engineering and field service technicians can create a complete accessories and upgrades plan for Stamtec and non-Stamtec Mechanical, Servo and Forging Presses. Our press accessories and upgrades programs can increase product quality, reduce tool wear and improve production efficiencies.

Stamtec accessories and upgrade plans can include:

Feeding and coil handling equipment provides the speed, quality and precision to exceed your most demanding stamping requirements.

Quick die change systems provide a number of important benefits, including:

Press controls and monitoring featuring advanced, userfriendly automation controls with fully programmable on-screen displays for easy set-up, start-up, operation and diagnostics

Press transfer systems integrating your existing systems and tooling with Stamtec and other stamping presses.

Please give Stamtec a call at 931-393-5050 for to discuss available Accessories and Upgrades.