Coil-handling and feeding systems, quick die change systems, & more to meet your specific needs

Coil-handling and feeding systems, quick die change systems, & more to meet your specific needs

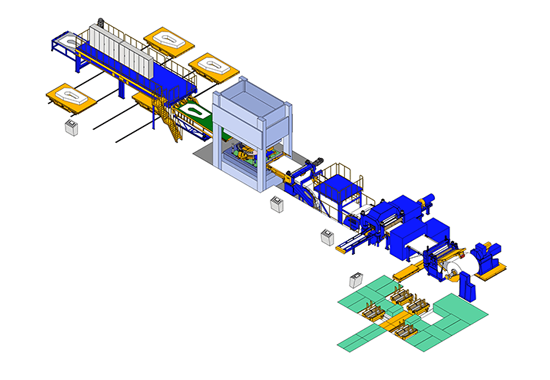

Get customized Stamtec blanking lines that effortlessly stamp out perfect parts, boost productivity, and drive your metalworking operations to new heights.

Stamtec’s expertise in blanking line technology sets us apart in the metal processing industry. As leaders in providing advanced manufacturing solutions, we understand the crucial role of a robust and efficient press blanking line in your production process. Our state-of-the-art lines are designed to deliver precision, reliability and superior performance, catering to a diverse range of material specifications and production demands.

Discover how our commitment to innovation and quality in blanking line systems can transform your production efficiency. For a comprehensive view of our offerings, explore all press-feeding production lines, where we showcase our range of solutions designed to meet the ever-evolving needs of the metal processing industry.

Blanking lines represent a cornerstone of modern manufacturing, and Stamtec stands at the forefront of this technology. These systems, known for their precision and versatility, are essential in shaping various materials to exact specifications. Stamtec's blanking lines are distinguished by their capability to handle diverse materials encompassing multiple thicknesses and weights. This versatility ensures that they can meet the demands of many industrial applications. Their expertise in press blanking line technology is a testament to their commitment to innovation and quality in metal forming and fabrication.

Blanking lines are high-tech cutting machines used in manufacturing. Here's a simple overview of what they do:

In short, a blanking line takes a roll of metal and cuts it into specific shapes in a highly efficient and precise way.

Blanking lines are vital in several manufacturing sectors, primarily for metal fabrication, where they excel in cutting big sheets of metal into smaller, more precise shapes and sizes. Key applications include:

The adaptability of blanking lines in handling different materials and thicknesses underscores their value in sectors where accuracy and efficiency are crucial.

Our press blanking line is a fusion of advanced technology and engineering excellence, designed to meet the rigorous demands of modern manufacturing. These lines feature:

Below, we've answered a few common questions about our blanking line. Please contact us for additional information.

We offer a range of customization options to meet specific industry needs, including varying material handling capacities and technological integrations. Additionally, we can tailor control systems and automation levels to suit specific production workflows.

Stamtec offers comprehensive support services, including full installation, training and ongoing service to ensure optimal performance and productivity. Our after-sales service provides clients with access to expert assistance whenever needed.

Our blanking lines handle a variety of materials, with adjustments available to accommodate different thicknesses and strengths. This flexibility ensures optimal performance across a wide range of material types and applications.

Stamtec provides comprehensive maintenance guidelines and support, ensuring each blanking line operates at peak efficiency for an extended period. Regular inspections and preventive maintenance are key aspects of their service offering.

When it comes to selecting the right blanking line for your production needs, Stamtec stands out with its tailored solutions and unmatched industry expertise. Our blanking line systems promise efficiency, precision, and reliability. With years of experience in the metal processing industry, Stamtec has developed a deep understanding of the challenges and needs of businesses like yours. Our comprehensive service support ensures that you have continuous assistance, from installation to maintenance, maximizing the longevity and performance of your equipment. Explore our separated coil handling and press feeding equipment to understand how we integrate superior technology with customer-centric service for your success.