Stamtec’s Mechanical Presses (a.k.a. OBG, OBS, OBI, or C-frame) undergo finite element analysis prior to manufacturing to ensure proper design, superior strength and maximum resistance to deflection

Stamtec’s Mechanical Presses (a.k.a. OBG, OBS, OBI, or C-frame) undergo finite element analysis prior to manufacturing to ensure proper design, superior strength and maximum resistance to deflection

The Stamtec G2 series two-point gap frame press (a.k.a. OBG, OBS, OBI, or C-frame) is designed for stamping relatively long, narrow parts at high single-stroking rates or in continuous mode, using either blanks or coil stock. The G2 series provides a large die area at a very economical price and can run progressive dies that need the longer bed area. The slide on these metal stamping presses is guided by six-point, full-length box type gibs, providing excellent control of slide alignment and accuracy throughout the entire stroke.

TONNAGE RANGE: 121 - 330

DELIVERY TIME: in stock or with quick delivery

Read the specs and press advantages below to learn more and then contact us by calling 931-393-5050 or submitting this online form for help identifying the gap frame press you need.

Stamtec presses can be customized to meet a wider range of SPM, stroke, rating point (BDC), bed and other specifications and dimensions.

| MODEL G2-110 SPECIFICATIONS | |||

|---|---|---|---|

| Type | V | H | |

| Capacity | US Tons | 121 | 121 |

| Metric Tons | 110 | 110 | |

| Rated tonnage point | in. | 0.196 | 0.118 |

| mm | 5 | 3 | |

| Stroke length | in. | 7.08 | 4.33 |

| mm | 180 | 110 | |

| Speed | SPM | 35 ~ 65 | 50 ~ 100 |

| Die height (S.D.A.U.) | in. | 15.75 | 13.77 |

| mm | 400 | 350 | |

| Maximum upper die weight | lbs. | 1,763.69 | 1,763.69 |

| kg | 800 | 800 | |

| Slide adjustment | in. | 3.93 | 3.93 |

| mm | 100 | 100 | |

| Bolster area (L-R X F-B) | in. | 70.86 x 25.59 | 70.86 x 25.59 |

| mm | 1800 x 650 | 1800 x 650 | |

| Bolster thickness | in. | 5.11 | 5.11 |

| mm | 130 | 130 | |

| Slide plate area (L-R x F-B) | in. | 55.11 x 19.68 | 55.11 x 19.68 |

| mm | 1400 x 500 | 1400 x 500 | |

| Slide plate thickness | in. | 2.75 | 2.75 |

| mm | 70 | 70 | |

| Shank hole | in. | Ø1.96 x .11 Pitch 12.59 | Ø1.96 x .11 Pitch 12.59 |

| mm | Ø50 x 3 Pitch 320 | Ø50 x 3 Pitch 320 | |

| Main Motor: Equipped with variable frequency drive | Hp x p | 15 x 4 | 15 x 4 |

| kW x p | - | - | |

| Sliding adjusting motor | Hp x p | 1 x 4 | 1 x 4 |

| kW x p | 0.75 x 4 | 0.75 x 4 | |

| Air pressure required | PSI | 71.12 | 71.12 |

| kg / cm2 | 5 | 5 | |

| Standard voltage is 480. Other voltages available at additional cost. | |||

| Parallelism: Slide to Bolster - 0.001" per foot or less | |||

| DIE CUSHION: 2-PAD / 2-CYLINDER | |||

| Capacity | lbs. | 7936.64 x 4409.24 | |

| kgs | 3.6 x 2 | ||

| Air pressure | PSI | 92.45 | |

| kg / cm2 | 6.5 | ||

| Stroke length | in. | 2.755 | |

| mm | 70 | ||

| Pad area | in. | 13.77 x 9.25 x 2pcs | |

| mm | 350 x 235 x 2pcs | ||

| MODEL G2-160 SPECIFICATIONS | |||

|---|---|---|---|

| Type | V | H | |

| Capacity | US Tons | 176 | 176 |

| Metric Tons | 160 | 160 | |

| Rated tonnage point | in. | 0.236 | 0.118 |

| mm | 6 | 3 | |

| Stroke length | in. | 7.87 | 5.11 |

| mm | 200 | 130 | |

| Speed | SPM | 30 ~ 55 | 40 ~ 85 |

| Die height (S.D.A.U.) | in. | 17.7 | 15.75 |

| mm | 450 | 400 | |

| Maximum upper die weight | lbs. | 2799.86 | 2799.86 |

| kg | 1270 | 1270 | |

| Slide adjustment | in. | 3.93 | 3.93 |

| mm | 100 | 100 | |

| Bolster area (L-R X F-B) | in. | 78.73 x 29.92 | 78.73 x 29.92 |

| mm | 2000 x 760 | 2000 x 760 | |

| Bolster thickness | in. | 5.9 | 5.9 |

| mm | 150 | 150 | |

| Slide plate area (L-R x F-B) | in. | 62.99 x 21.65 | 62.99 x 21.65 |

| mm | 1600 x 550 | 1600 x 550 | |

| Slide plate thickness | in. | 2.75 | 2.75 |

| mm | 70 | 70 | |

| Shank hole | in. | Ø1.96 x .11 Pitch 13.77 | Ø1.96 x .11 Pitch 13.77 |

| mm | Ø50 x 3 Pitch 350 | Ø50 x 3 Pitch 350 | |

| Main motor: Equipped with variable frequency drive | Hp x p | 20 x 4 | 20 x 4 |

| kW x p | - | - | |

| Sliding adjusting motor | Hp x p | 1 x 4 | 1 x 4 |

| kW x p | 0.75 x 4 | 0.75 x 4 | |

| Air pressure required | PSI | 71.12 | 71.12 |

| kw / cm2 | 5 | 5 | |

| Standard voltage is 480. Other voltages available at additional cost. | |||

| Parallelism: Slide to Bolster - 0.001" per foot or less | |||

| DIE CUSHION: 2-PAD / 2-CYLINDER | |||

| Capacity | lbs. | 13889.12 x 4409.24 | |

| kgs | 6.3 x 2 | ||

| Air pressure | PSI | 102.41 | |

| kg / cm2 | 7.2 | ||

| Stroke length | in. | 2.755 | |

| mm | 70 | ||

| Pad area | in. | 16.14 x 10.23 x 2pcs | |

| mm | 410 x 260 x 2pcs | ||

| MODEL G2-200 SPECIFICATIONS | |||

|---|---|---|---|

| Type | V | H | |

| Capacity | US Tons | 220 | 220 |

| Metric Tons | 200 | 200 | |

| Rated tonnage point | in. | 0.236 | 0.118 |

| mm | 6 | 3 | |

| Stroke length | in. | 9.84 | 5.9 |

| mm | 250 | 150 | |

| Speed | SPM | 25 ~ 45 | 35 ~ 70 |

| Die height (S.D.A.U.) | in. | 19.68 | 17.72 |

| mm | 500 | 450 | |

| Maximum upper die weight | lbs. | 3240.79 | 3240.79 |

| kg | 1470 | 1470 | |

| Slide adjustment | in. | 4.72 | 4.72 |

| mm | 120 | 120 | |

| Bolster area (L-R X F-B) | in. | 94.48 x 33.07 | 94.48 x 33.07 |

| mm | 2400 x 840 | 2400 x 840 | |

| Bolster thickness | in. | 6.29 | 6.29 |

| mm | 160 | 160 | |

| Slide plate area (L-R x F-B) | in. | 72.83 x 25.59 | 72.83 x 25.59 |

| mm | 1850 x 650 | 1850 x 650 | |

| Slide plate thickness | in. | 3.74 | 3.74 |

| mm | 95 | 95 | |

| Shank hole | in. | Ø1.96 x .11 Pitch 14.76 | Ø1.96 x .11 Pitch 14.76 |

| mm | Ø50 x 3 Pitch 375 | Ø50 x 3 Pitch 375 | |

| Main motor: Equipped with variable frequency drive | Hp x p | 20 x 6 | 20 x 6 |

| kW x p | 15 x 6 | 15 x 6 | |

| Sliding adjusting motor | Hp x p | 2 x 4 | 2 x 4 |

| kW x p | 1.5 x 4 | 1.5 x 4 | |

| Air pressure required | PSI | 71.12 | 71.12 |

| kw / cm2 | 5 | 5 | |

| Standard voltage is 480. Other voltages available at additional cost. | |||

| Parallelism: Slide to Bolster - 0.001" per foot or less | |||

| DIE CUSHION: 2-PAD / 2-CYLINDER | |||

| Capacity | lbs. | 22046.23 x 4409.24 | |

| kgs | 10 x 2 | ||

| Air pressure | PSI | 96 | |

| kg / cm2 | 6.75 | ||

| Stroke length | in. | 3.14 | |

| mm | 80 | ||

| Pad area | in. | 21.25 x 13.77 x 2pcs | |

| mm | 504 x 350 x 2pcs | ||

| MODEL G2-250 SPECIFICATIONS | |||

|---|---|---|---|

| Type | V | H | |

| Capacity | US Tons | 275 | 275 |

| Metric Tons | 250 | 250 | |

| Rated tonnage point | in. | 0.28 | 0.14 |

| mm | 7 | 3.5 | |

| Stroke length | in. | 11.02 | 5.9 |

| mm | 280 | 170 | |

| Speed | SPM | 30 ~ 60 | 30 ~ 60 |

| Die height (S.D.A.U.) | in. | 21.65 | 17.72 |

| mm | 550 | 450 | |

| Maximum upper die weight | lbs. | 3439.2 | 3439.2 |

| kg | 1,560 | 1,560 | |

| Slide adjustment | in. | 4.72 | 4.72 |

| mm | 120 | 120 | |

| Bolster area (L-R X F-B) | in. | 106.29 x 35.43 | 106.29 x 35.43 |

| mm | 2700 x 900 | 2700 x 900 | |

| Bolster thickness | in. | 6.26 | 6.26 |

| mm | 160 | 160 | |

| Slide plate area (L-R x F-B) | in. | 82.67 x 27.55 | 82.67 x 27.55 |

| mm | 2100 x 700 | 2100 x 700 | |

| Slide plate thickness | in. | 3.74 | 3.74 |

| mm | 95 | 95 | |

| Shank hole | in. | Ø1.96 x .11 Pitch 17.71 | Ø1.96 x .11 Pitch 17.71 |

| mm | Ø50 x 3 Pitch 450 | Ø50 x 3 Pitch 450 | |

| Main motor: Equipped with variable frequency drive | Hp x p | 25 x 6 | 25 x 6 |

| kW x p | 19 x 6 | 19 x 6 | |

| Sliding adjusting motor | Hp x p | 2 x 4 | 2 x 4 |

| kW x p | 1.5 x 4 | 1.5 x 4 | |

| Air pressure required | PSI | 71.12 | 71.12 |

| kw / cm2 | 5 | 5 | |

| Standard voltage is 480. Other voltages available at additional cost. | |||

| Parallelism: Slide to Bolster - 0.001" per foot or less | |||

| DIE CUSHION: 2-PAD / 2-CYLINDER | |||

| Capacity | lbs. | 30864.72 x 4409.24 | |

| kgs | 14 x 2 | ||

| Air pressure | PSI | 128.01 | |

| kg / cm2 | 9 | ||

| Stroke length | in. | 3.14 | |

| mm | 100 | ||

| Pad area | in. | 25.19 x 18.50 x 2pcs | |

| mm | 640 x 470 x 2pcs | ||

| MODEL G2-300 SPECIFICATIONS | |||

|---|---|---|---|

| Type | V | H | |

| Capacity | US Tons | 330 | 330 |

| Metric Tons | 300 | 300 | |

| Rated tonnage point | in. | 0.28 | 0.14 |

| mm | 7 | 4 | |

| Stroke length | in. | 11.02 | 6.69 |

| mm | 280 | 170 | |

| Speed | SPM | 20 ~ 35 | 30 ~ 60 |

| Die height (S.D.A.U.) | in. | 21.65 | 21.65 |

| mm | 550 | 550 | |

| Maximum upper die weight | lbs. | TBD | TBD |

| kg | TBD | TBD | |

| Slide adjustment | in. | 4.72 | 4.72 |

| mm | 120 | 120 | |

| Bolster area (L-R X F-B) | in. | 106.30 x 35.43 | 106.30 x 35.43 |

| mm | 2700 x 900 | 2700 x 900 | |

| Bolster thickness | in. | 7.48 | 7.48 |

| mm | 190 | 190 | |

| Slide plate area (L-R x F-B) | in. | 94.01 x 31.50 | 94.01 x 31.50 |

| mm | 2388 x 800 | 2388 x 800 | |

| Slide plate thickness | in. | 3.74 | 3.74 |

| mm | 95 | 95 | |

| Shank hole | in. | TBD | TBD |

| mm | TBD | TBD | |

| Main motor: Equipped with variable frequency drive | Hp x p | 30 x 6 | 30 x 6 |

| kW x p | 22 x 6 | 22 x 6 | |

| Sliding adjusting motor | Hp x p | 2 x 4 | 2 x 4 |

| kW x p | 1.5 x 4 | 1.5 x 4 | |

| Air pressure required | PSI | 71.12 | 71.12 |

| kw / cm2 | 5 | 5 | |

| Standard voltage is 480. Other voltages available at additional cost. | |||

| Parallelism: Slide to Bolster - 0.001" per foot or less | |||

| DIE CUSHION: 2-PAD / 2-CYLINDER - specs available on request | |||

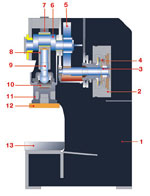

Extra-long, box-type centered gibs guide the slide during the working portion of the stroke. The design of this mechanical stamping machine provides full control of left-to-right and front-to-back slide alignment.

Extra-long, box-type centered gibs guide the slide during the working portion of the stroke. The design of this mechanical stamping machine provides full control of left-to-right and front-to-back slide alignment.

Heavy, one-piece welded steel frame is fully stress relieved and designed to resist deflection, providing more accurate stampings and longer die life.

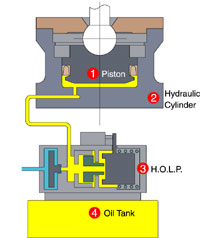

Fast-response hydraulic overload relieves the pressure of a tonnage overload in milliseconds, stopping the press immediately and protecting press and dies from damage.